Instead of just endlessly editing the post on wingsails, I thought I’d write up separate posts to document my progress(?) and put them in a specific category, navigable from the main menu bar.

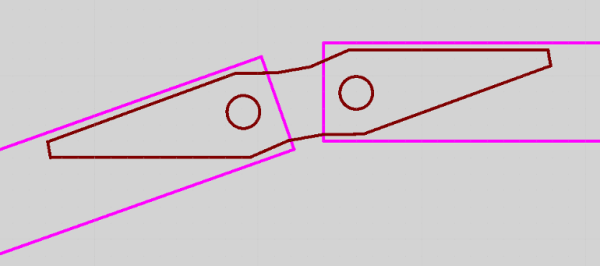

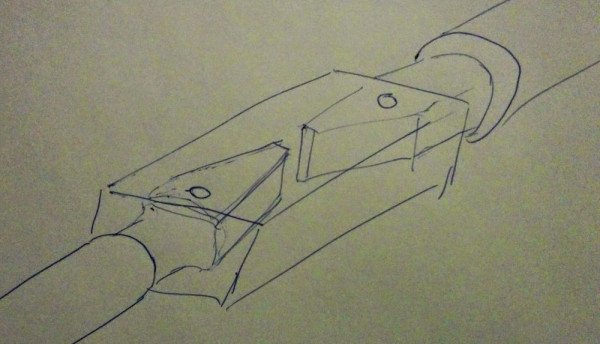

Today I’ve been doing some actual measurements and developed a type of hinge that would work in practice as well, compared to my previous designs which wouldn’t have. This one uses either 60 mm wide rectangular tubing, where the wedge goes roughly 14 cm into the batten, or 50 mm wide, where it would only go in 11 cm. Maybe 11 cm would be enough, maybe not. I have to do some more research and/or ask people more knowledgeable on these kinds of things.

Batten types

I still haven’t been able to decide how to construct the fore/aft batten assembly. Here are my thoughts so far:

1. Rectangular tubes both fore and aft with the above described hinge. The battens would probably be unnecessarily heavy. It would on the other hand be the easiest build, not only for the battens/hinge, but also for the U-shaped jaw.

2. Round tubes both fore and aft with a “middle hinge box” made out of rectangular (for example 60x40x2 mm) tubing. This would be the most effective way as the round battens would save weight compared to the heavy rectangular ones required to make the wedges go deep enough into the tubes.

3. Something in between? Rectangular or square battens would be stronger for their weight if the load was simply on a horizontal plane, but since the sheets are imposing both a horizontal and vertical load, I think round battens might be better. Decisions, decisions.

Different batten specs

Here are the results of calculations I made of different aluminium profiles I’ve been considering. S is the section modulus (yy for the wider, xx for the narrower faces). The section modulus for a diagonal load should be somewhere around 70%, which is also the downside of a four-sided profile when the load direction is unknown or not constant.

Rectangular

60x40x2.5

Sxx: 7825

Syy: 6174

Weight: 1.28 kg/m

50x30x2.5

Sxx: 4906

Syy: 3593

Weight: 1.02 kg/m

Calculate properties of hollow rectangle tube

Round

50×2

Sxx/Syy: 3480

Weight: 0.81 kg/m

45×2

Sxx/Syy: 2781

Weight: 0.73 kg/m

40×2

Sxx/Syy: 2161

Weight: 0.65 kg/m

Calculate properties of hollow round tube

I’m on the clock here and should make a decision about this within roughly two weeks, as I will then have a car available to me for a few days, which allows me to go shopping for aluminium tubing (and wood).

Deadlines, the ultimate inspiration.

Hi Oscar

I’ve also been working on wingsails with David and like you am interested in making the battens in aluminum. I’m toying around with a floating hinge adapted from one of David’s previous designs. I worry a bit about hinge designs that use rigid pins as part of the joint. In order to allow reasonable amounts of articulation the pins have to be very close to the end of the tube. If the sail lifts as it is articulating, there could be very large forces on very small pins at the articulation points. I’ll send you my drawing if your interested.

I’ve settled for round aluminium battens and I’ve planned to use “double-cone hinges”, which I will make either out of wood or solid PVC rod. So no pins. I’m curious about your solution though, if you wouldn’t mind sharing your drawing I’d be happy to take a look at it. You can reach me at [email protected]