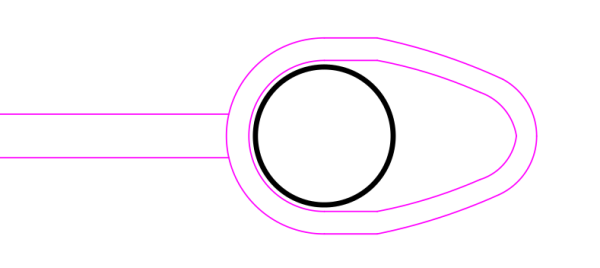

How to construct this part of the project has been somewhat unclear to me since I started, even if I know there are a bunch of different solutions. Let’s take a look at the front part of the batten assembly with (aluminium) batten + nose:

I could either build it as one piece, which would require the mast to be stepped into the noses, or the noses put in place over the top of the mast. Neither alternative seems too attractive, so I would like to have a method of assembling and taking the noses apart at deck level, with the mast in place. This means I have to construct the noses in two pieces. I’ve toyed around with a few ideas so far. Hand drawn because I’m (still) faster with pen and paper than I am using CAD. 🙂

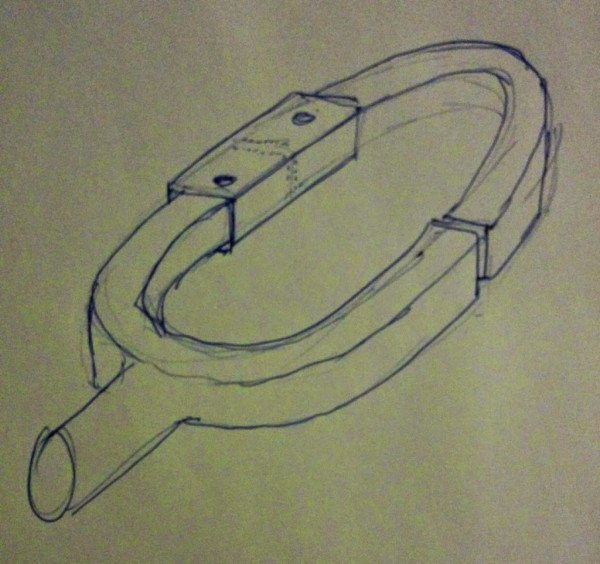

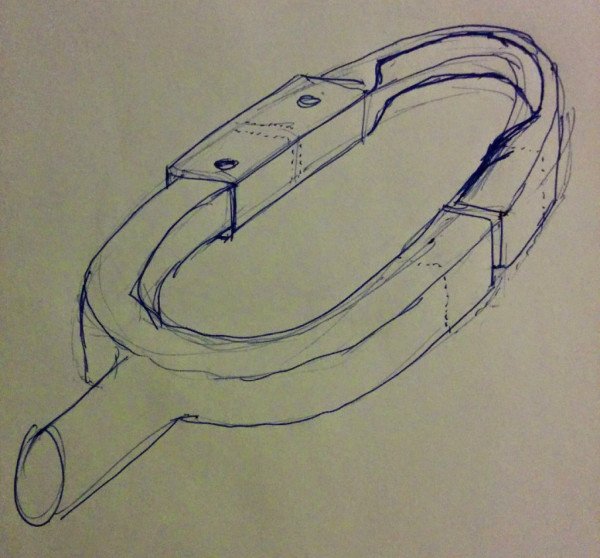

This would be a relatively simple construction with the nose built in one piece and then cut apart. The joint could be easily made using square/rectangular aluminium tubing with bolts through to secure them in place. Or probably better, because the front part of the nose isn’t loadbearing, to cut some material off it. Something like this:

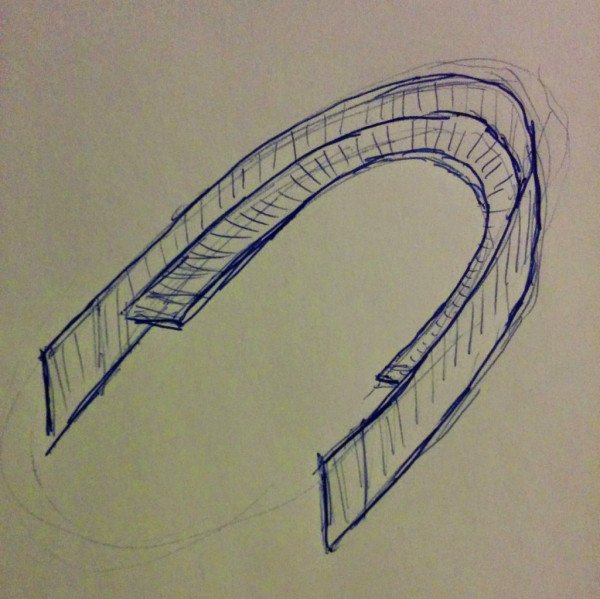

I’ve also thought about doing something like this:

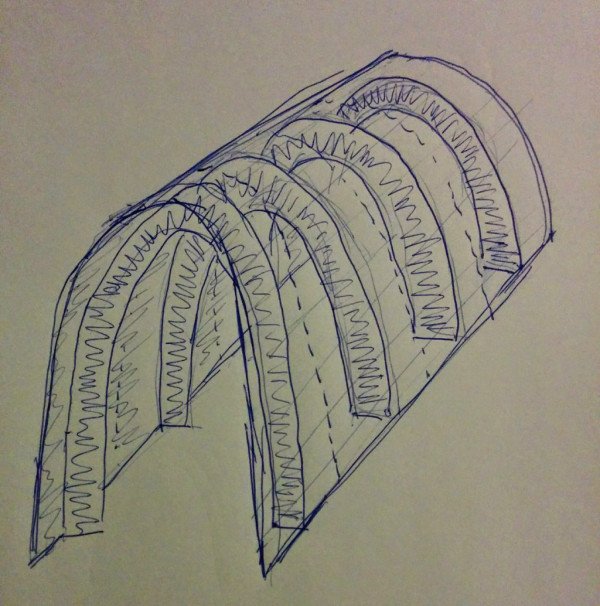

But this form is probably more suited for the luff formers in the middle of the panels, between the battens. They could easily be “mass-produced” using this principle:

The “mould” would need some thicker end-pieces to clamp the plywood to and to be robust enough. So in essence, a) cut out the horizontal lying parts, b) bend a piece of plywood over them, c) glass the whole thing and d) cut the pieces apart (four pieces in the above drawing). Oh, and the plywood should obviously be longer in the ends. Won’t bother making a new drawing.

Construction material is plywood + GRP. More on this as thoughts progress.